Regardless of the a lot of advantages of precision machining, firms ought to be careful when specifying shut tolerances.

CNC machining is precise plenty of to create higher-quality factors with the close-use software of numerical Management. The material flexibility of this method permits the fabrication of lots of parts.

CNC machining offers its use on a variety of medically Secure materials. Given that the procedure is suited to 1-off custom parts, it's got several applications during the health-related industry. The restricted tolerances afforded by CNC machining are important to the high performance of machined healthcare elements.

As with every manufacturing procedure, the special benefits of CNC machining tell the kind of applications for which it may be used.

Several of these parts overlap with other industries including aerospace and electronics. The ability of CNC machines to offer on-desire alternative parts and upgraded components are especially beneficial Within this industry. Hence, it works very well for parts that demand consistent innovation and security.

EDM applications usually include the hardest metals due to The issue of machining them utilizing milling machines. EDM is often applied to generate holes, slots, and tapers in gears.

CNC machining is practically nothing short of a wonder for manufacturers, furnishing significant-velocity manufacturing with total automation and ultra-substantial precision. The plenty of great things about the CNC machining procedure have made it relevant in several manufacturing industries.

Tolerances are substantial in precision CNC machining operations mainly because they lower production expenditures and turnaround times. As essential as These are, they need much knowledge and time to get effectively. CNC machines have a typical tolerance of 0.005 inches.

Kind milling Procedure helps to machine curves and straight traces in just one Minimize. Shaped cutters can use for vertical and horizontal milling machines and can ground to the contour from the workpiece. The contour is sometimes ground with an individual-point fly cutter.

Bredikhin denied sending the invitation. He did not answer after becoming told the document appears to bear his signature.

CNC technology continues to be a cornerstone of your energy industry since the 1970s, enabling the production of complex and higher-overall performance parts.

aside from these things machine product reputation tracking and tool interfacing are a number of important options.

A cutting tool is really a form of instrument meant to cut or condition many check here materials, Primarily wood, plastic, and metals. Notably in the Manufacturing Industry, these tools are widely used for product removal procedures. A Read through a lot more…

Medical Units: Precision is from the utmost great importance On the subject of clinical equipment. CNC machining may be used to make surgical instruments, implants, and orthopaedic products, for example.

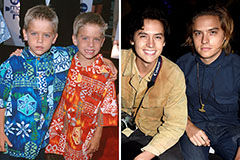

Dylan and Cole Sprouse Then & Now!

Dylan and Cole Sprouse Then & Now! Lark Voorhies Then & Now!

Lark Voorhies Then & Now! Jennifer Love Hewitt Then & Now!

Jennifer Love Hewitt Then & Now! Danica McKellar Then & Now!

Danica McKellar Then & Now! Christy Canyon Then & Now!

Christy Canyon Then & Now!